Welcome to our blog dedicated to the attractive world of Germanium and other photoelectric materials.

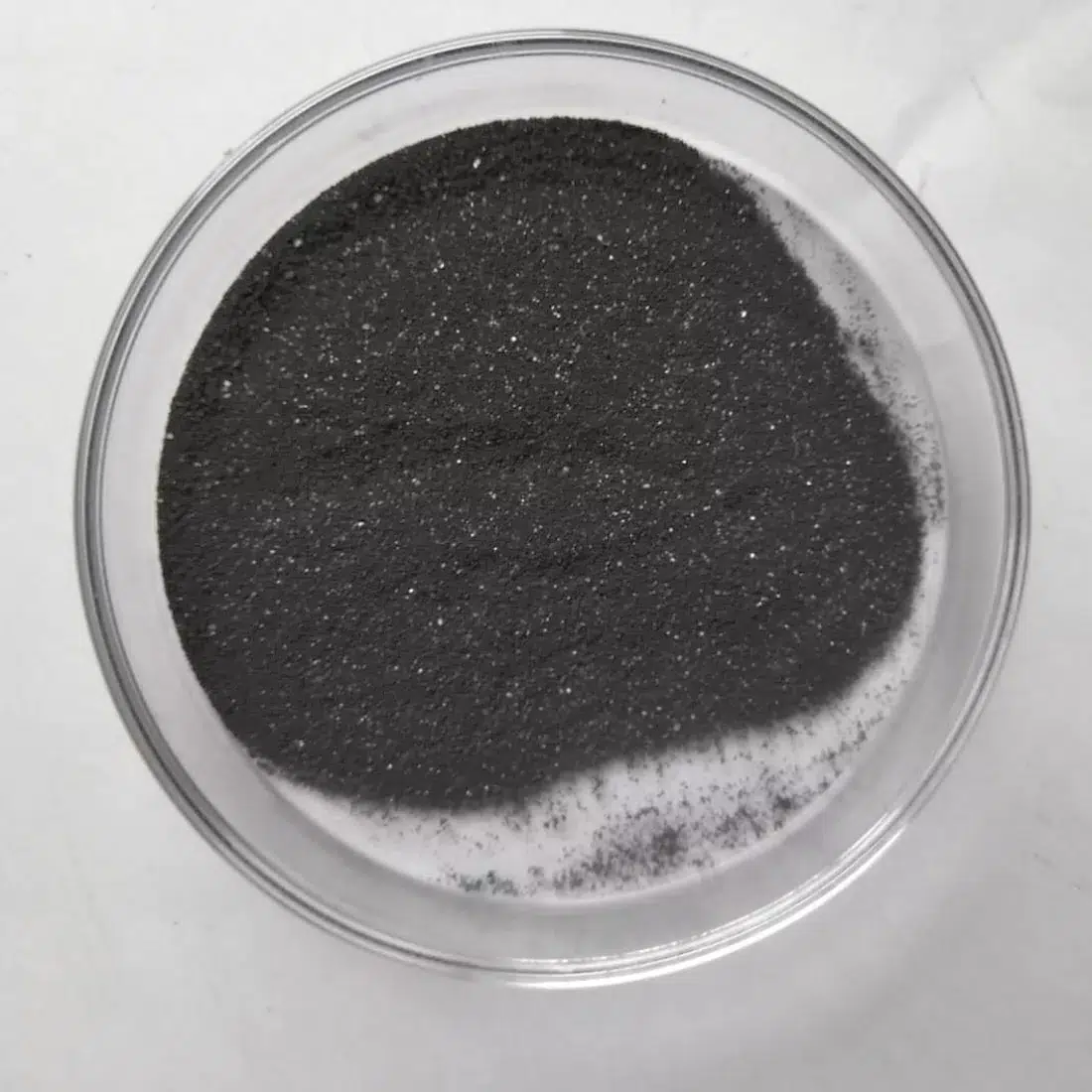

Weekly Market Update Germanium Powder Price

This week germanium powder prices continued the previous downward trend and the our quotation has reached below USD2400/kg.

How Does Valuable Germanium Stone Make us More Energized?

Human cells resonate and resonate with the fluctuations emanating from the germanium stone, making human cells and tissues more energetic and promoting blood circulation.

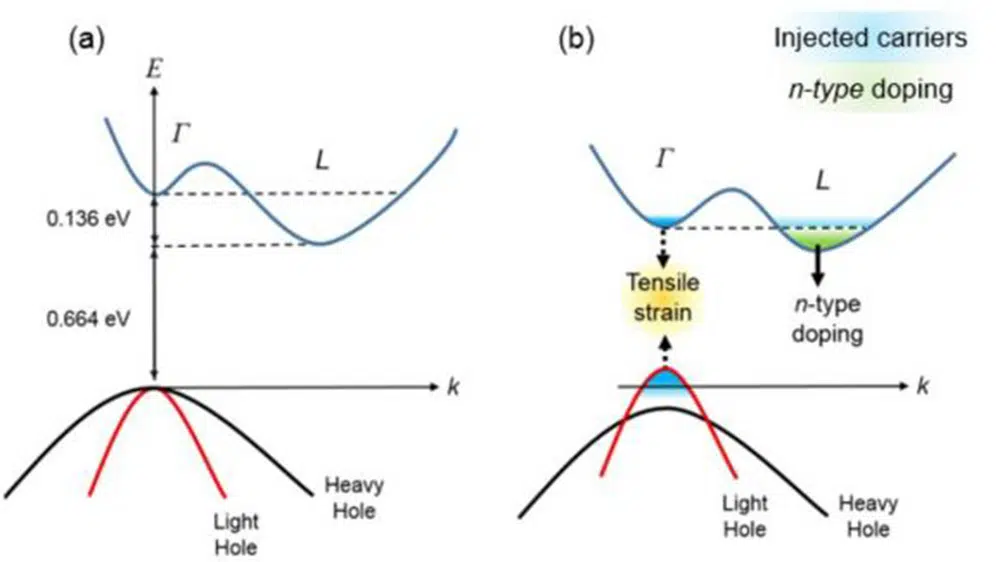

What is Causing High Purity Germanium Price to Skyrocket?

Recently germanium price “straight up” hit a record high.